Our Clients

- US Army Corps of Engineers (Superfund Project)

- King of Prussia Technical Corporation Site PRP Group (Superfund Project)

- Springfield Township Site PRP Group (Superfund Project)

- US Naval Facilities Engineering

- United States Department of Energy

- Westinghouse Hanford Company

- DuPont

- Daimler-Chrysler

- ARCADIS

- Eco Recycling Systems (France)

- City of Montreal (Canada)

- HERA AG Ambiental (Spain)

- BEFESA Gestion de Residuos Industriales (Spain)

- The Monsanto Company

- Honeywell International

- Parsons Engineering Science, Inc.

- RMI Environmental Services

- ELM Group

- Hoffman La Roche

- Langan Engineering

- Troy Chemical Company

- Penbrook Homes / Abito

SMART Excavation & Site Remediation Project Management

ART can provide overall SMART excavation and site remediation project management services for complicated projects. SMART excavation and soil segregation can provide a significant project cost savings.

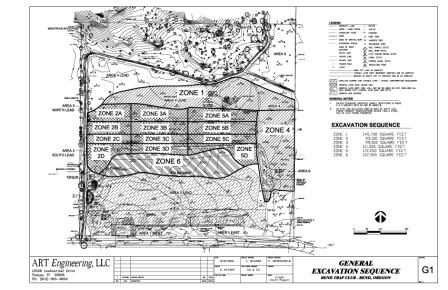

| Example 1: Bend Trap Club

For the Bend Trap Club site remediation, the goal was to complete the remediation to residential standards for Lead, Arsenic and Polynuclear Aromatic Hydrocarbon (PAH). During initial treatability study performed by ART is was concluded that the lead pellets could be effectively removed from lead-only impacted soils to meet residential cleanup levels for soil after treatment. However, for soils impacted by Lead pellets and PAH, residential standards could not be achieved for PAH. As these soils were characteristically hazardous (exceeding TCLP regulatory limit for Pb), these soils were excavated selectively, stabilized and disposed at a permitted landfill. The selective excavation and stabilization provided significant cost savings. |

Excavation Sequence & Soil Management Plan |

|

|

||

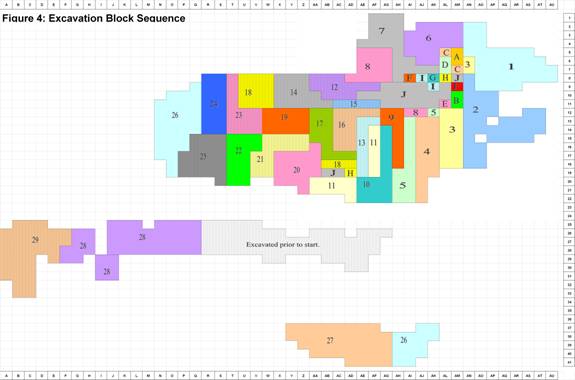

| Example 3: Vineland Chemical Superfund Site For the Vineland Chemical Superfund Site, ART provided a detailed soil excavation, soils management and blending plan to provide a constant feed within design parameters of the soil treatment plant. This approach resulted that all soils including "Hot Spot" areas were amenable to soil treatment. This provided significant project cost savings. The filter cake residue resulting from the soil washing operation was disposed at a permitted landfill. |

Excavation Sequence & Blending Plan |

|